Does Stereo Measurement Measure Pit Depth?

in modern measurement technology, stereo measurement, as an important tool, is widely used in many fields, including geological exploration, construction engineering and environmental monitoring. The core of stereo measurement is to obtain the three-dimensional information of the object from two or more perspectives, so as to realize the accurate measurement of the shape, size and depth of the object. This paper will discuss whether stereo measurement can effectively measure the pit depth, and analyze its advantages and limitations in practical application.

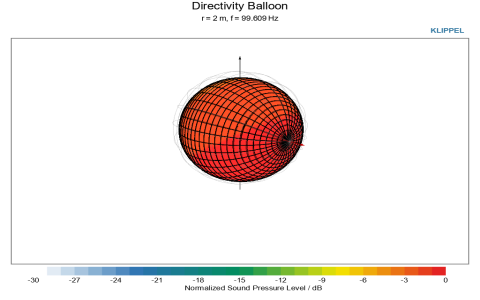

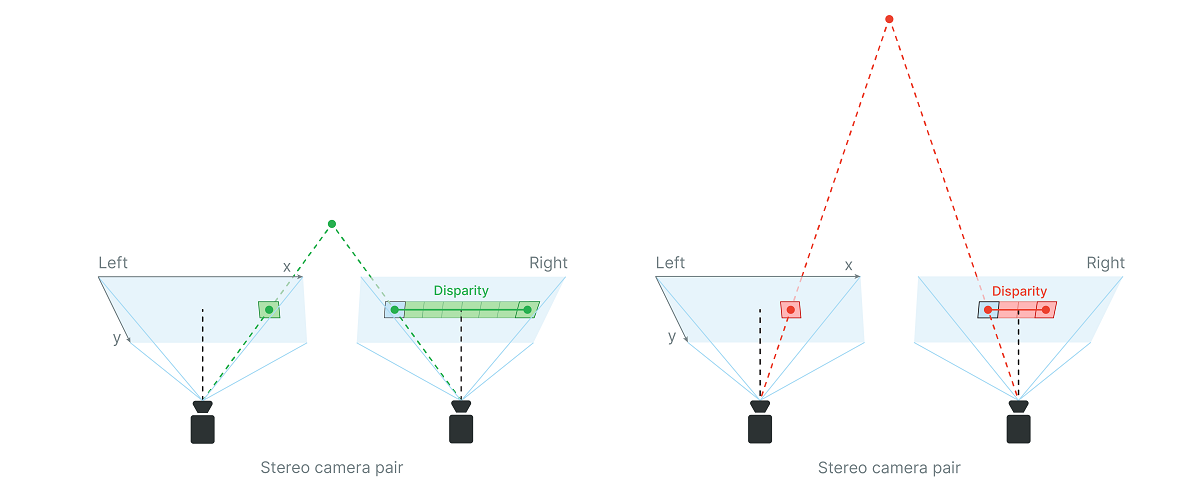

the basic principle of stereo measurement is to use two or more cameras to shoot the same object from different angles, and calculate the three-dimensional coordinates of the object by comparing these images. This method has obvious advantages in depth measurement, because it can provide more information than traditional single-view measurement. Especially when measuring complex terrain or irregular surface, stereo measurement can capture subtle changes more accurately.

when measuring the pit depth, the application of stereo measurement is particularly important. Traditional measuring methods, such as using a ruler or a sounder, are often limited by the skills of operators and environmental conditions. Stereo measurement can automatically identify the edge and bottom of the pit through image processing technology, thus achieving higher measurement accuracy. By comparing images from different perspectives, stereo measurement can effectively eliminate errors caused by illumination changes or object occlusion.

However, stereo measurement also faces some challenges when measuring the pit depth. First of all, the shape and size of the pit will affect the measurement results. For smaller or deeper pits, stereo measurement may be difficult to obtain enough viewing angle, which leads to inaccurate depth measurement. In addition, environmental factors such as water surface reflection and soil color change may also interfere with the clarity of the image and affect the reliability of the measurement.

despite these challenges, the application of stereo measurement in pit depth measurement still has broad prospects. With the continuous progress of technology, the accuracy and stability of stereo measuring equipment are constantly improved, which can better adapt to various complex environments. In recent years, the stereo measurement method combined with UAV technology has gradually emerged, which can carry out efficient depth measurement in a wider range. This method not only improves the efficiency of measurement, but also reduces the risk of manual operation.

In practical application, stereo measurement has been widely used in mining, civil engineering and environmental monitoring. For example, in mining, stereo measurement can help engineers accurately evaluate the depth and shape of pits, so as to make a reasonable mining plan. In urban construction, stereo measurement can provide important data for the layout of underground pipelines and ensure the safety and effectiveness of construction.

generally speaking, stereo measurement shows great potential in pit depth measurement. Although it faces some technical challenges, its advantages in accuracy and efficiency make it an indispensable measuring tool. With the continuous development of technology, the application scope of stereo measurement will be further expanded, providing more accurate measurement solutions for all walks of life.